Is Reverse Osmosis Water Distilled? Understanding the Key Differences

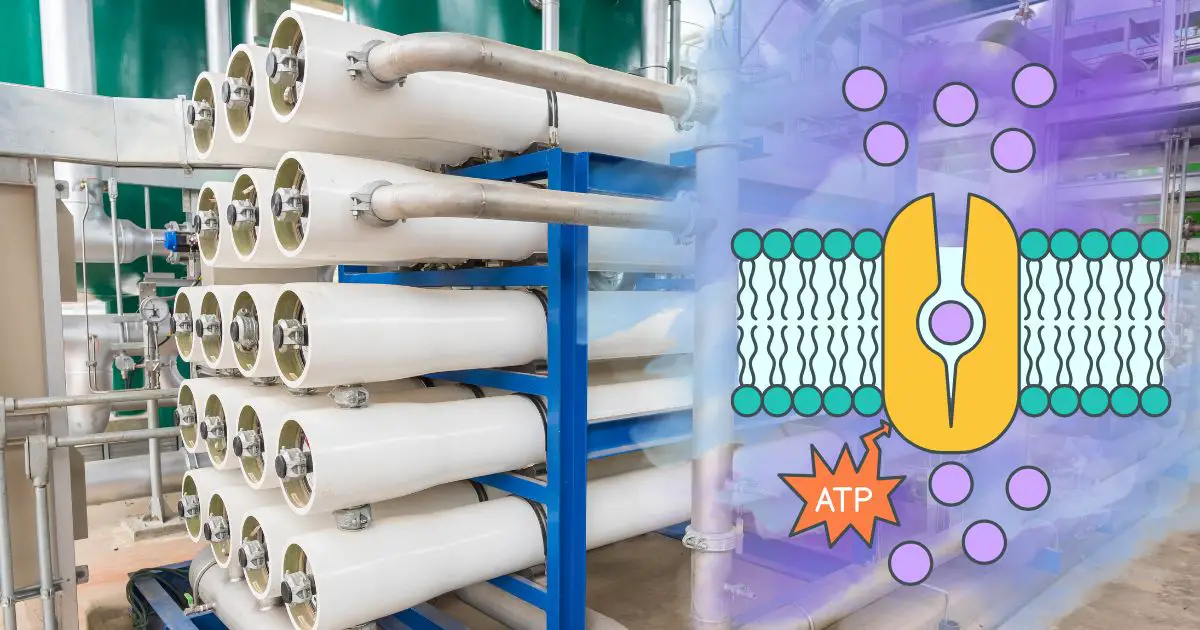

Water purification is essential for safe drinking water, and two of the most common purification methods are reverse osmosis (RO) and distillation. But are they the same? Is reverse osmosis water distilled water? In this article, we will break down the differences and similarities between reverse osmosis water and distilled water, their benefits, and which … Read more