In this article, I addresses both the important question what is cooling tower & how many types of cooling tower?

Are you ready to learn?

Let’s start..

Cooling Tower Definition:

Cooling tower is simply a one type of heat exchange equipment where air & water comes in to the direct contact with each other.

The main function of cooling tower is to reject heat of hot water into atmosphere & cooling down the water for further reuse. There are different types of cooling tower

Evaporation of water is responsible for majority of heat rejected from water in cooling tower. Typically 75% to 80% of heat is removed from water by evaporation process. Remaining heat removed by passing airflow through the cooling tower.

Cooling Tower is also a water saver equipment where you can save huge amount of water by recycling the water. Open recirculation system is very popular in all types of industries because of water recycling feature.

In most of the industrial process, water is widely used as a cooling medium because it is very efficient, readily available & relatively cheap.

Types of Cooling Tower:

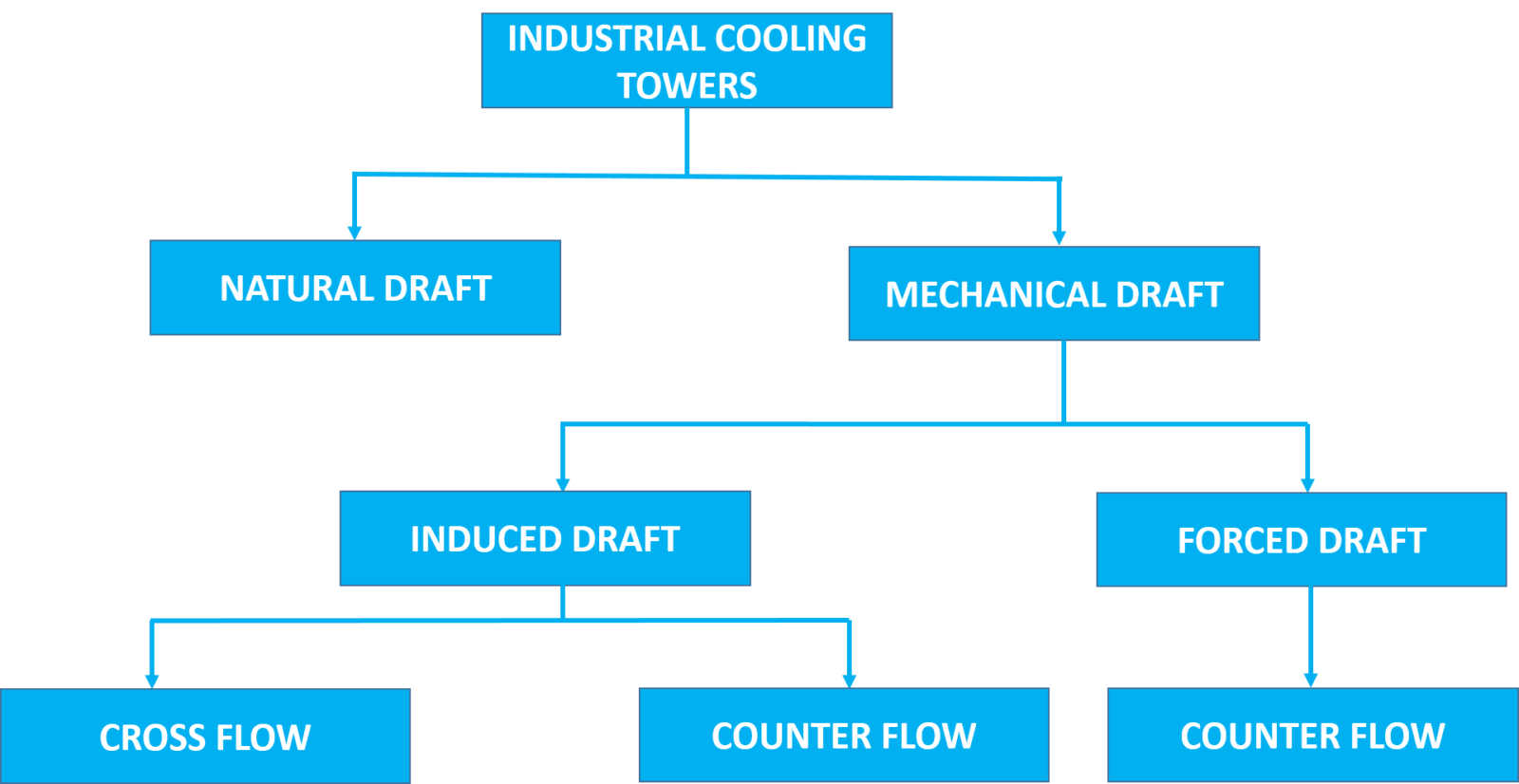

Cooling towers are mainly divide in two categories.

- Natural Draft

- Mechanical Draft

Let us discuss each of them in detail.

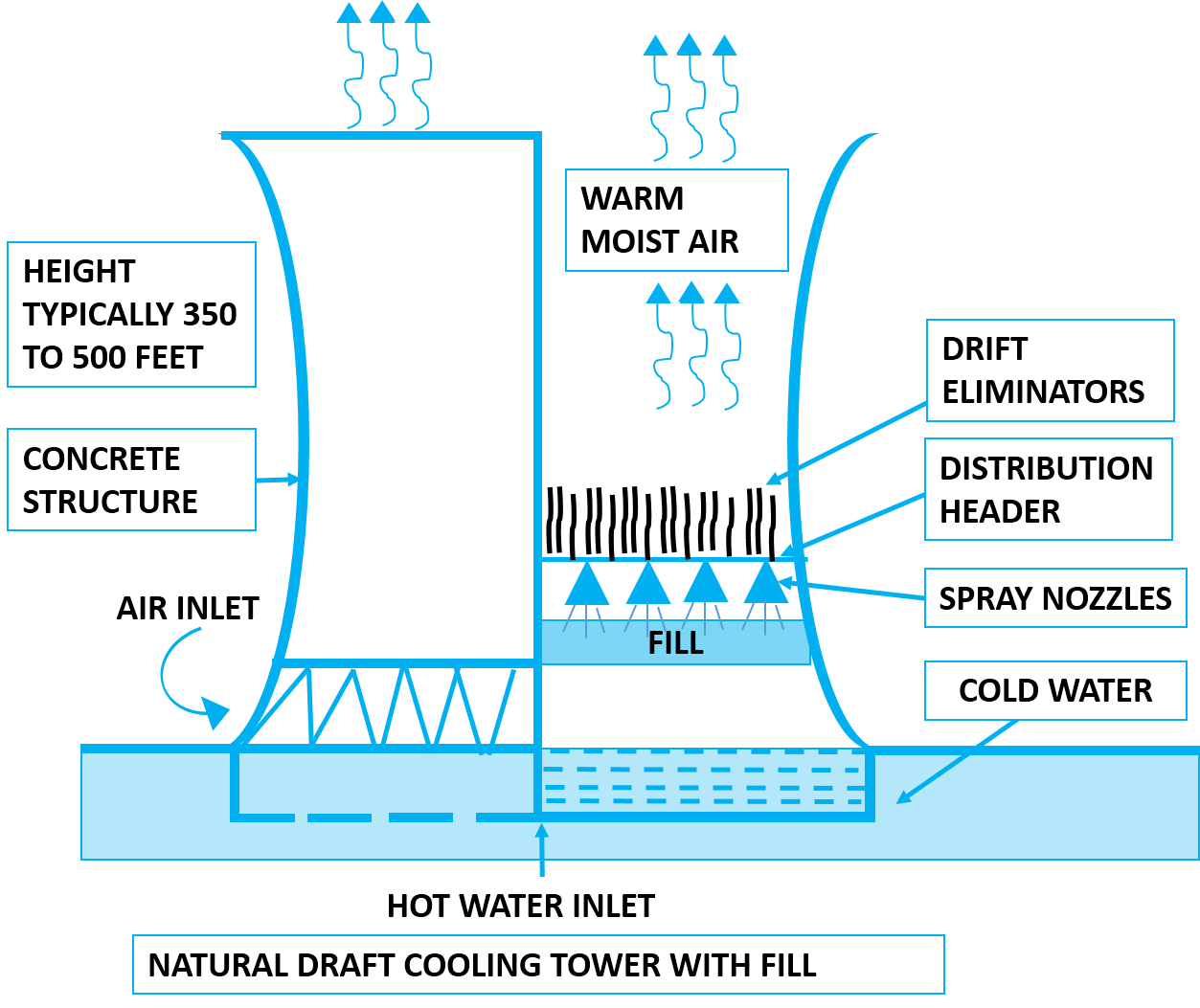

Natural Draft Cooling Tower:

Natural draft cooling towers use very large concrete chimneys to introduce air through the media. Warm, moist air naturally rises due to the density difference compared to outside air which is cool & dry.

Hyperbolic shape of tower drive moist air upwards (buoyancy) & pulls cold air into the tower. Due to the large size of these towers typically 350 to 500 feet, they are generally used for water flow rates above 45,000 m3/hr. usually, large utility power stations uses these types of towers.

The principle is same as mechanical draft tower but here fan unit is missing because Heat removed from water by natural draft. This type of tower reduce both operating & energy consumption cost due to its natural draft given by height & stack dimension. Additionally, natural draft cooling tower has a long service life, low noise emissions & low maintenance.

Mechanical Draft Cooling Tower:

Mechanical draft cooling towers utilize power driven motor fans to force or draw air through the tower. These large fans force or suck air through circulated water.

The water then falls downward over fill surfaces, which helps increase the contact time between the water and the air and maximizes heat transfer between them.

Cooling rates of Mechanical draft towers depend upon their fan diameter and speed of operation.

Mechanical draft towers are available in the following airflow arrangements:

- Induced draft

- Forced draft

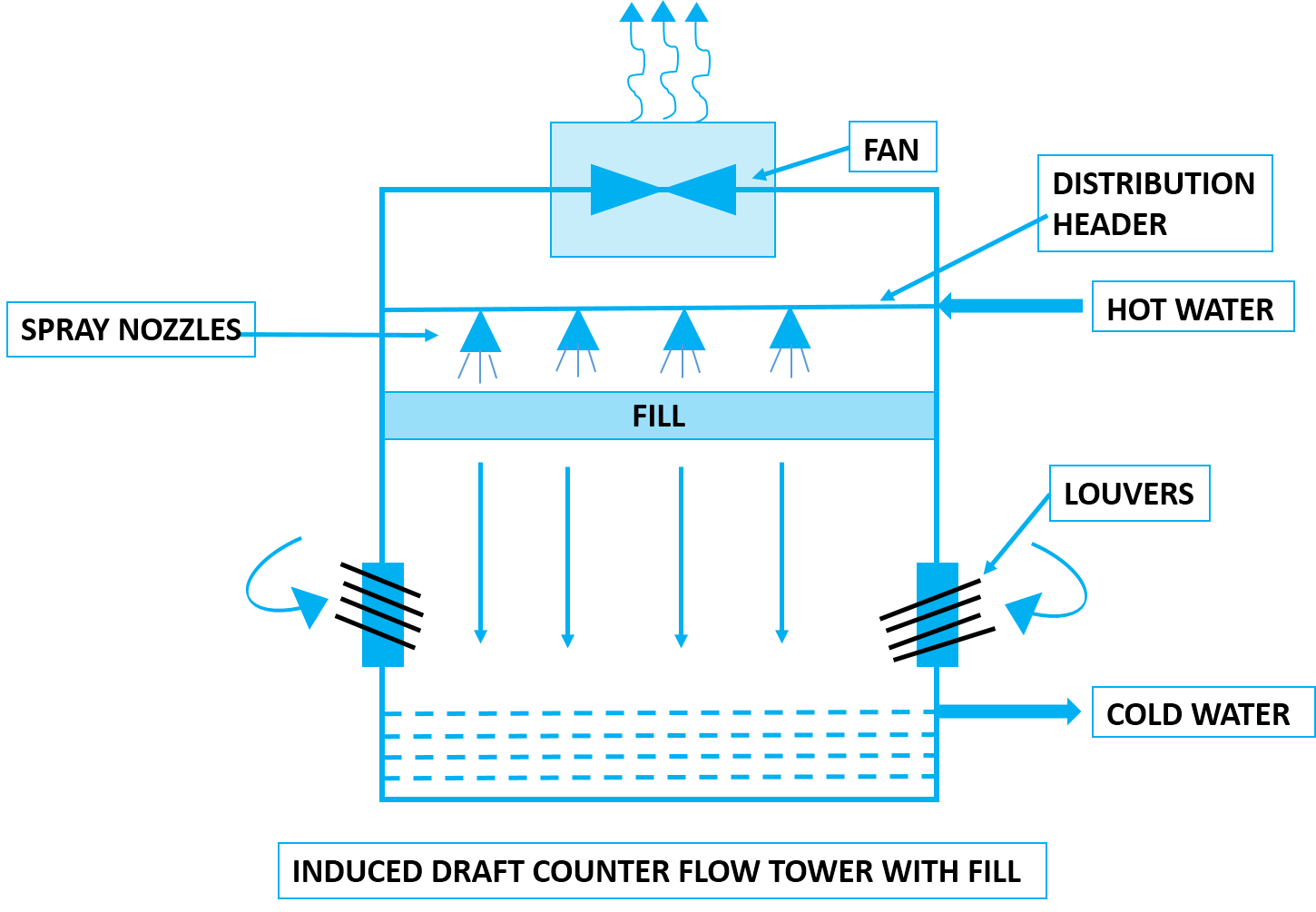

Induced Draft Cooling Tower:

An Induced draft cooling tower is a mechanical draft tower with a fan at the discharge to pull air through it. The fan induces hot moist air out the discharge.

This produces low entering and high exiting air velocities, reducing the possibility of recirculation in which discharged air flows back into the air intake.This fan/fill arrangement is also known as “Draw-through”.

This is the diagram of counter flow induced draft design. in this design hot water enters at the top & air enters from the bottom and exit at the top of the tower.

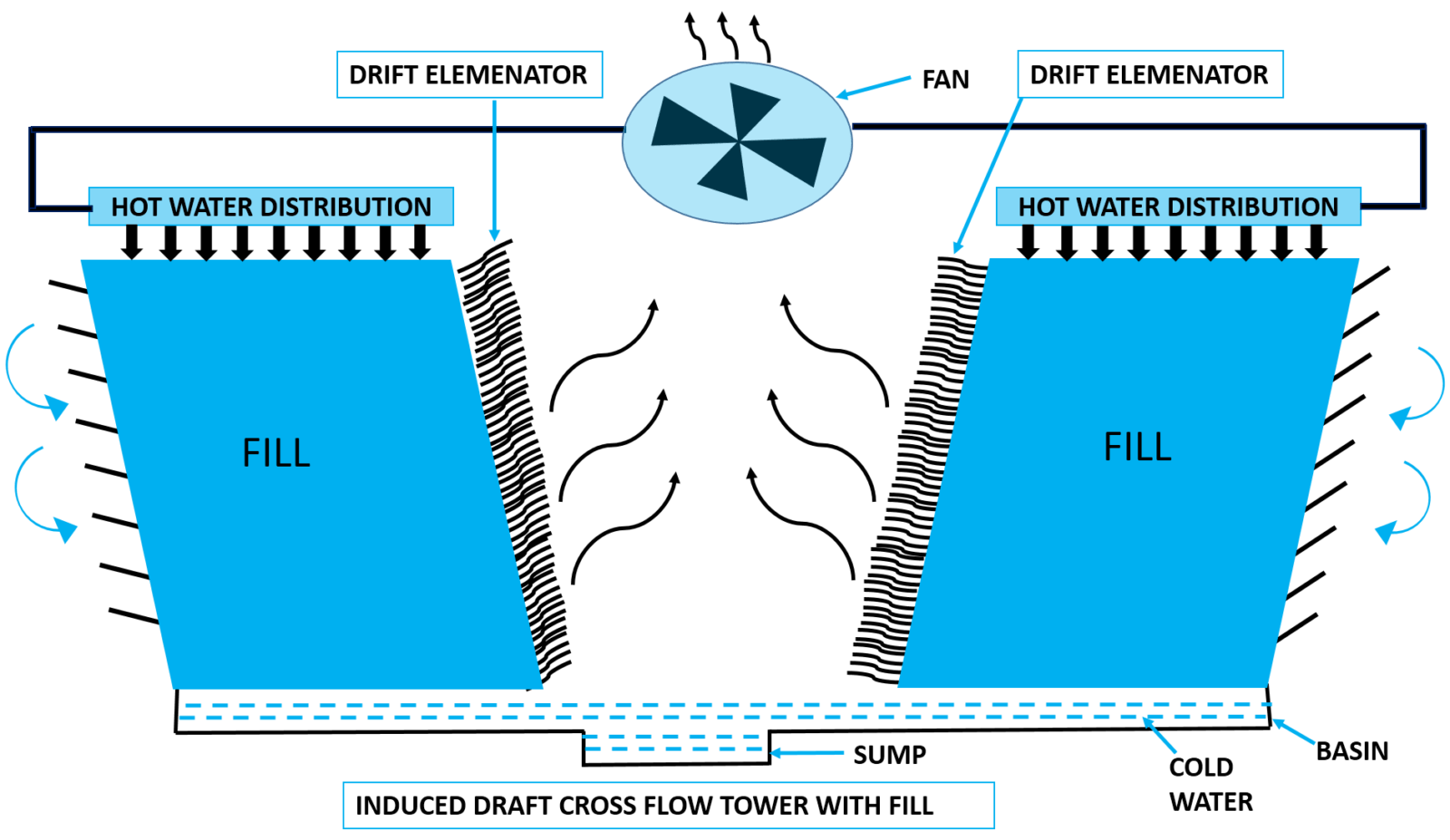

This is the diagram of induced draft cross flow cooling tower. In this arrangement water enters from the top and passes over the fill but here the difference is in the air inlet path. Air is enters form the side of the tower as you can see in the diagram. An induced draft fan draws air across the wet fill and expels it through the top of the structure.

Forced draft:

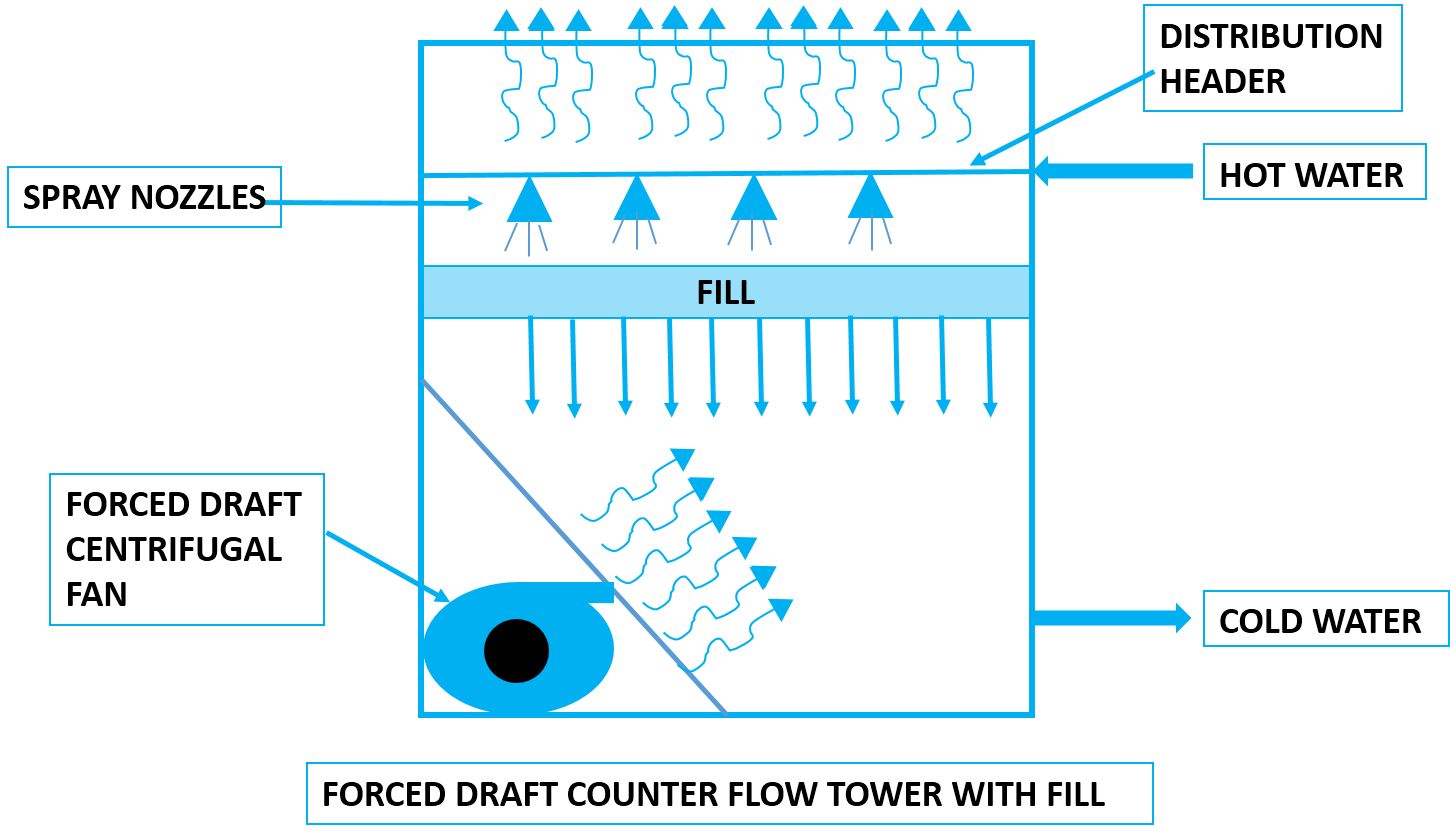

A Forced draft cooling tower is a mechanical draft tower with a blower type fan at the intake. The fan forces air into the tower, creating high entering and low exiting air velocities.

The low exiting velocity is much more susceptible to recirculation. With the fan on the air intake, the fan is more susceptible to complications due to freezing conditions.

Another disadvantage is that a forced draft design typically requires more motor horsepower than an equivalent induced draft design.The benefit of forced draft tower is ability to work with high static pressure. You can easily install in more confined spaces and even in some indoor situations.

This fan/fill geometry is also known as “Blow-through”.

Based on the movement of Air and the Hot Water Flow these can be classified into two types:

- Cross flow

- Counter flow

Cross Flow Cooling Tower:

Cross flow is a design in which the air flow is perpendicular to the water flow. Air flow enters one or more vertical faces of the cooling tower to meet the fill material.

Water flows (perpendicular to the air) through the fill by gravity. The air continues through the fill and thus past the water flow into an open plenum area.

A distribution or hot water basin consisting of a deep pan with holes or nozzles.

Gravity distributes the water through the nozzles uniformly across the fill material.

Counter Flow Cooling Tower:

In a counter flow design, the air flow is directly opposite to the water flow. Air flow first enters an open area beneath the fill media and then drawn up vertically.

The water sprayed through pressurized nozzles and flows downward through the fill, opposite to the air flow.

Both Cross flow and Counter flow designs can be used in Mechanical draft cooling towers.

Hope, this article is clear your concept of what is cooling tower & types of cooling towers.