The selection of a types of cooling system is basically depends on the quantity & quality of the water source which is available. Each of these systems has it’s own advantages & disadvantages.The Three main types of cooling water system are:

- Once Through Cooling System

- Closed Recirculating System

- Open Recirculating System

Let’s discuss one by one in detail:

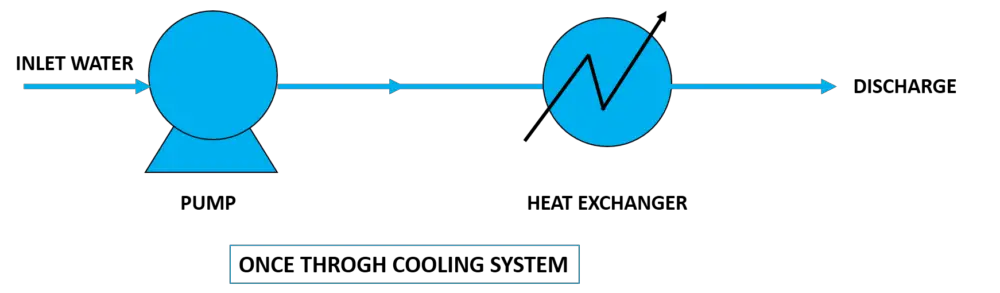

# 1. Once Through Cooling System:

Once through system means water circulates in the system only once & then discharged from the system. It means cooling water passes through the heat exchangers only once.

This system is only applicable where plenty of water is available. This is the major drawback of this system.

The possibility of chemical treatment is also limited because all added chemical discharged from the system after completion of first cycle which is environmentally & economically not favorable. Normally, only chlorination is helpful to this type of the system for microbiological control.

Pros:

- Low Capital Cost

- Low Operating Cost

- Low Temperature Scale

Cons:

- Discharge of large quantity of hot water

- Absence of adequate chemical control for scaling

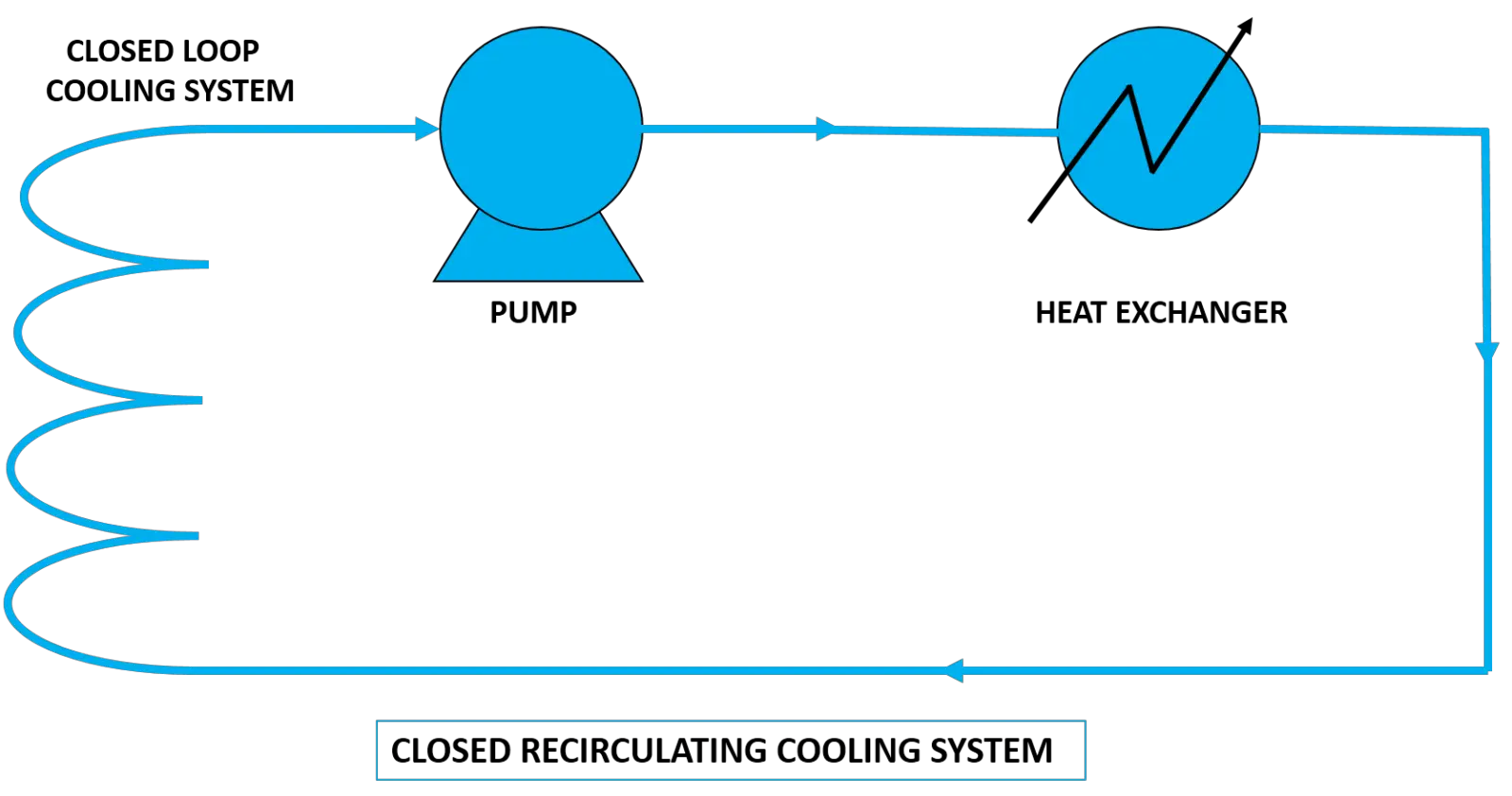

2. Closed Recirculating Cooling System:

In closed recirculating system cooling water is circulates in closed loop means within the system pipes and heat exchangers. The heat absorbed from the plant process is generally dissipated by air-cooling.

Loss from the system is very less and little make up is required, hence concentration of salt in the water is very less.

Deposition /scale formation is not a problem in this system. Major problem may be corrosion, which can be easily controlled by use of suitable corrosion inhibitor.Generally,Nitrite based inhibitors are very effective.

Pros:

- Very limited make-up required

- Small volume of chemical required to treat

- Scaling is not a problem because of high quality make up water

- Less susceptible to biological fouling

Cons:

- Only economically applicable for small cooling system

- Requires another cooling system to run this system

- Expense of additional heat exchangers

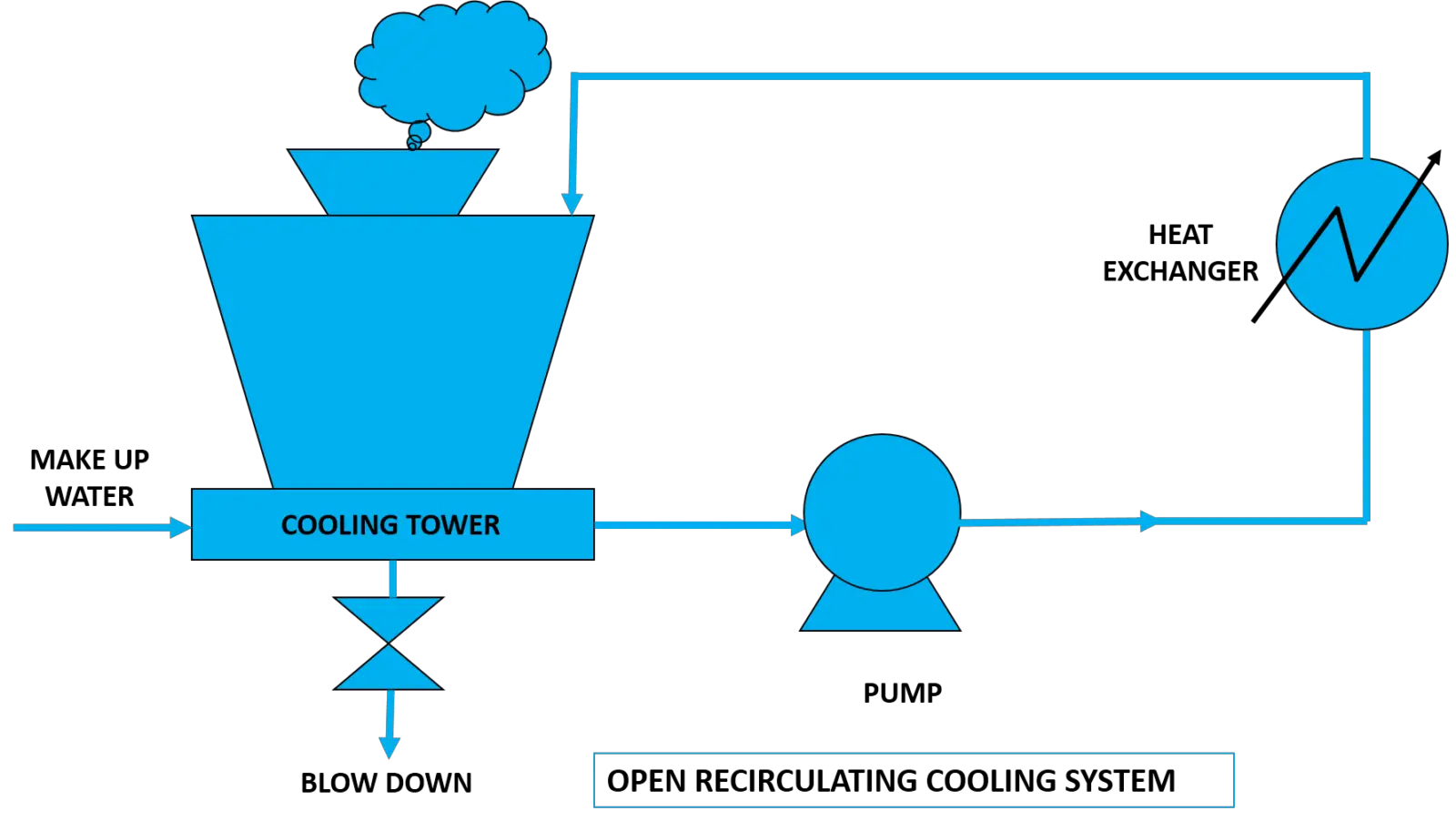

# 3. Open Recirculating Cooling System:

This is the most popular & widely used system in almost all industries. This type of system is applicable where water supply is restricted or hot effluent can’t be tolerated for environmental reasons.The good quality of water requires for this system to allow recycling of water.

When water evaporates dissolved solids present in water don’t evaporates but they gradually concentrates. This will lead to corrosion & scaling problems in the system. It can control by cooling water treatment programs. Generally, the heat exchanger & piping system are made of carbon steel.

In this system water recirculates according to design cycles of concentration which is also known as COC.

Chemical treatment is essential for this system. You can increase cycles of concentration of cooling tower with the help of proper treatment programs. You can also save large amount of water by operating cooling tower on higher COC.

Pros:

- Saves large amount of water

- Reduce discharge rate of water

- Chemical control is possible

Cons:

- Higher capital cost

- Higher operating cost

In conclusion, Open recirculating system is best choice because it saves large amount of water & you can also control scaling & corrosion by applying suitable chemical treatment.

Closed system requires additional cooling system this is the major disadvantage & only applicable for small systems while on the other hand to operate once through cooling system plenty of water is required & Chemical control is also not possible.